Tools for well completion with pumping ESP.

Delrio S.A.S offers mechanical and electrical solutions for the simultaneous production of Oil crude, the sand handling and the well testing that use the electric submergible pumping system as an artificial system drive.

Mechanical equipment

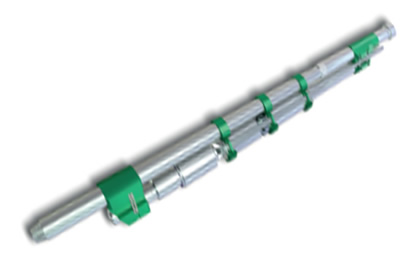

Y/ Tool Equipment

- Allow access to the well with production register and so with BES equipment.

- Allow casing opening and closing with BES equipment.

- Stimulation with Coiled tubing.

- Fluid injection.

- Real time operation of Wireline and Coiled Tubing.

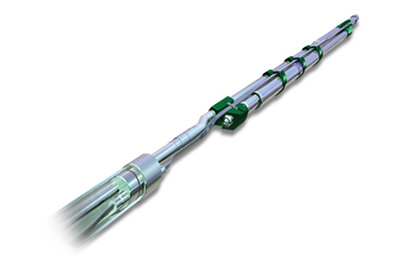

- Dual System ESP

• Saves workover costs

• Allows production of zone in an independent manner.

• Prevents that the greater area overrun the lower area.

• Increases the flow or the lifting

• Achieves the production´s objectives with the standard’s ESP

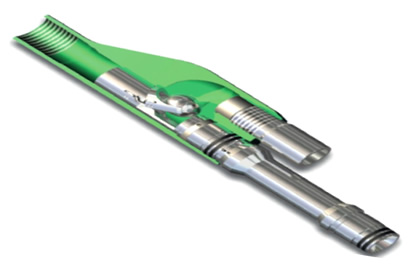

- BOP CAN system

- • Allows making production testing into the well.

• Allows to defined parameters of the production into the well.

• Saves operation time to make pull up the well.

• Provides a security bar when the well is on production.

Electrical equipments

- Wellhead dimensions

• Suitable for high pressure wells

• Suitable for high temperature well

• Suitable under H2S and CO2 conditions

• High current and high voltage

• Reducible system good cost benefit performance

• Steel completed built construction or manufacturing, also high resistance to water

• Able to fit in several configurations of well head equipment

• Able to work under 6feet of head submergence

| Current rating | 100- 140-160-180-220 |

| Pressure rating | 5000 PSI |

| Temperature rating | 255- 300 0 F |

| Voltage rating | 5000 V |

| Well head dimension | 2 3/8 EUE– 2 1/8 EUE – 3 1/8 EUE |

- Packing penetrator

• Able to handling mechanical tension in the production string.

• Suitable for high temperature well.

• Suitable under H2S and CO2 conditions.

• High current and high voltage.

• Reducible system good cost benefit performance.

• Able to fit in a concentering packer 3 leg system.

| Current rating | 140-180 |

| Pressure rating | 5000 PSI |

| Temperature rating | 265- 300 0 F |

| Voltage rating | 5000 V |

| Wellhead dimension | 1.9 NU – 2 3/8 EUE |

Patented equipment

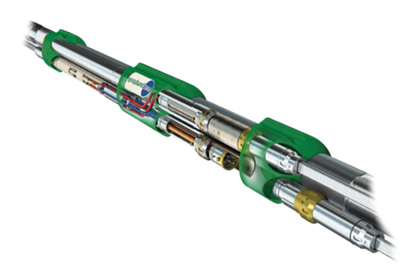

- The Switch

• Standard configuration with one power cable from sub farce

• Set up

• Just one cable is able to set up two ESP downhole

• No splicing

• Standard feed throw configuration for the packer cable

• Save work over cost up to 50%

• Save nonproductive time when completion is changed

- Y-Check

• Use a bowl valve which is activated mechanically

• Save slackline cost, save non-operating times on field

• Allow access with production lock bellow ESP equipment

• Allow sliding sleeves interventions

• Stimulation with Coiled Tubing

• Fluids injection

• Operations of WireLine and Coiled Tubing

- Sensors – Gauges

• Improves ESP´s run life

• Prevent non operative´s time

• ESP diagnoses on real time

• Lower operation cost

• Production optimization

Escribanos/Mailed-us-delrioco@delrio.com.co

Copyrights © 2018 . Powered by DELRIO.